- Greater yield, low energy consumption

- High yield, less waste, Great filling accuracy

- Easy installation, use & maintenance

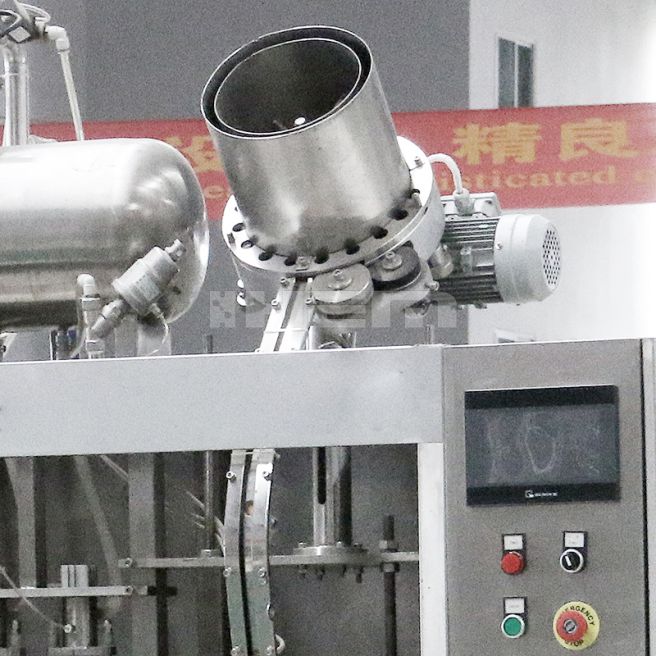

360BPM(6BPM) Semi-Automatic Beer Bottling Machine is specifically designed to beer filling and include double pre evacuation as a standard feature on some models to ensure ultra low dissolved oxygen DO’s are maintained during the filling operation. The combination of high quality robust machine construction along with close attention to the needs of clean in place CIP ensures our beer fillers deliver efficient reliable bottling production. As well as filling a wide range of all beer types, such as lagers, ales, stouts, unfiltered wheat beers and bottle conditioned beers HG's beer fillers can also be used for filling cider, hard cider, sparkling wines as well as carbonated soft drinks.

| Item | Parameters |

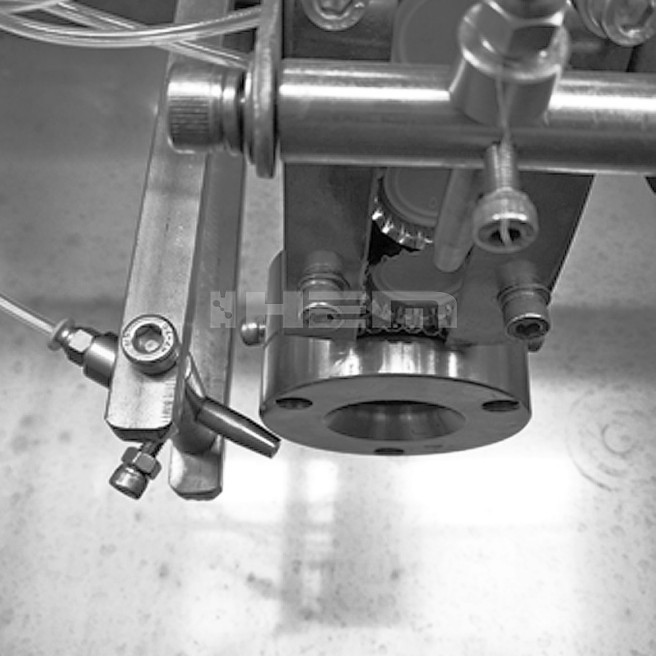

| Washing heads | 4 |

| Filling heads | 4 |

| Capping heads | 1 |

| Rated capacity(500ml one bottle) | 300-500BPH |

| Suitable bottle type | Bottle height: 150~300mm Bottle diameter: Φ50~Φ85mm |

| Sterile air consumption | 0.2 m3/min(0.4~0.6Mpa) |

| CO2 consumption | 260g/100L |

| Vacuum pump | 0.2 m3/h |

| Control voltage DC | 24V |

| Water | 0.5-1T |

| Power | 1KW Hopper motor: 0 .18KW Vacuum pump motor: 0.37 KW (the user prepares) Rinsing pump motor: 0.37KW (the user prepares) |

| Weight | 250KG |

| Dimensions | 1550×550×2220 (length×wide×high) |

| Item | Production capacity | Filling method | Material | Dimensions |

| BM-SEMI-4-4-1 | 240-360BPH | Isobaric filling | SUS304 | 1550*550*1750mm |

| BM-6-6-1 | 500-800BPH | Isobaric filling | SUS304 | 1520*1125*2350mm |

| BM-8-8-3 | 800-1000BPH | Isobaric filling | SUS304 | 1850*1600*2500mm |

| BM-16-16-6 | 2000BPH | Isobaric filling | SUS304 | 2300*1900*2500mm |

| BM-40-40-10 | 8000-10000BPH | Isobaric filling | SUS304 | 4200*3000*2700mm |